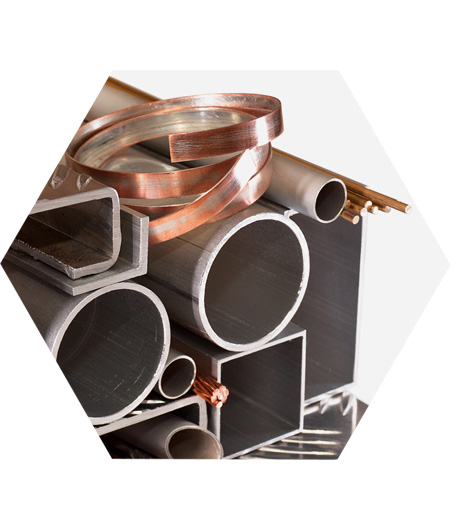

In addition to producing a wide range of property security equipment, we also provide comprehensive treatment of materials such as metal, steel and aluminum. We produce metal products designed for the needs of our customers according to submitted technical documentation or a specific model. Our aid often begins at the design stage which we develop according to the expectations of our customers.

Endless possibilities and short deadlines are possible due to our state-of-the-art machine park in which use such machines for metalwork as: TRUMPF 3030 Laser, TRUMPF 3050 Laser, TRUMPF TruPunch 5000 Punch, TRUMPF 500 R Punch, Safran Press Brake, TRUBEND 5085 Press Brake, GILARDI AMMACHINERY Press Brake, Dalex welding machines..

The materials which we subject to treatment at the request of our customers include

hot-and cold-rolled metal sheet, stainless steel and acid-resistant steel, aluminum and manganese metal sheet.

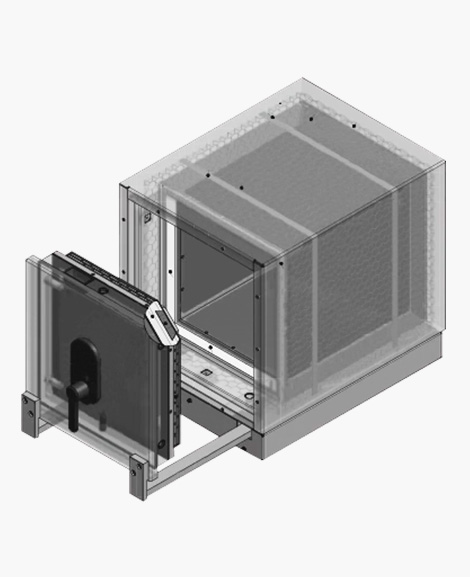

The change of a new safe parameters with technical documentation is done by one click.

VARNISHING

GALVANIZING

CHROMING

ANODISING

ALUMINIUM

INSULATING PLATE

HEAT ABSORBING PANELS

STAINLESS STEEL

FIRE-RESISTANT CONCRETE

STEEL FRONT PLATE

MANGANESE

ALUMINIUM

STEEL

HARDENED STEEL

ACID-RESISTANT STEEL

Our company not only manufactures the highest quality security products but also takes care of professional customer service. Highly qualified advisors will listen to your expectations and will provide you with a piece of advice in choosing a solution that will fully respond to all your needs.

The experience we gathered as well as a wide range of our products let us meet your expectations.

Visit us directly or contact us by telephone or e-mail. We will answer all your questions and provide comprehensive information on our products. This will help you make an optimal decision and protect your property to the greatest possible extent. For more information, see the "Contact" section.

We take care to provide our customers with comprehensive security and to establish lasting relationships with them. Therefore, our work is not limited to manufacturing of safes. We also provide their installation, training in respect of utilization, servicing, and disposal if necessary.

In case of any problems, feel free to contact us immediately to obtain our expert advice or eliminate a defect. We provide repairs under warranty, as well as post-warranty repairs.

Our experts carry out periodic inspections and perform equipment maintenance. If necessary, we perform emergency opening of safes. We provide assistance in case of problems with electronic locks or codelocks and we repair any defects. We also repair safes, strongboxes or security cabinets if they have been damaged during a burglary attempt.